Discover Precision and Performance: Introducing AM TZM Powder for Additive Manufacturing

We are proud to unveil the newest product to our additive manufacturing powder arsenal: AM TZM Powder. As a company committed to providing cutting-edge solutions to our customers, we’re elated to introduce this dynamic addition to our ever-evolving lineup. AM TZM powder is poised to continue helping customers expand their production and success in the additive manufacturing realm.

What sets AM TZM Powder apart?

The unique aspect of AM TZM Powder lies in its composition – it is a fully alloyed TZM powder. Unlike other blends, this powder is truly alloyed, ensuring consistent and reliable performance in your additive manufacturing processes.

Features and Highlights

Our commitment to quality remains unwavering with AM TZM Powder. Here are some of the key features and highlights that our AM customers are sure to appreciate:

High Density and Low Oxygen: AM TZM Powder boasts high density and low oxygen content, guaranteeing excellent mechanical properties and enhanced performance in your 3D printed components.

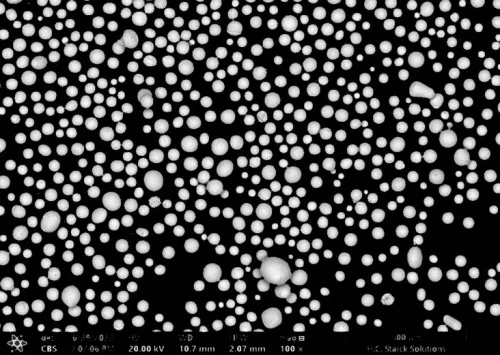

Excellent Flowability: The powder’s exceptional flowability ensures smooth and reliable processing, reducing the risk of defects and optimizing the efficiency of your additive manufacturing operations.

Particle Size Options: We offer AM TZM Powder in two particle size options to accommodate different additive manufacturing techniques. Choose from L-PBF (-50+15µm) and DED (-150+40µm) particle sizes. Additionally, if you have specific size requirements, we are equipped to produce custom sizes tailored to your needs.

Flexible Quantities: Whether you require a small batch or large-scale production, we’ve got you covered. AM TZM Powder is available in quantities ranging from 5kg to metric ton sizes, ensuring you have the right amount for any project.

Convenient Stocking: For small quantities, there is a ready-to-ship inventory at the Coldwater, MI plant. However, larger quantities or custom sizes may have a lead time of approximately 12 weeks. Rest assured, we strive to minimize turnaround times while ensuring top-notch quality.

Versatile Applications:

While AM TZM Powder is indeed the ideal choice for powder bed laser fusion applications, its versatility extends to various other additive manufacturing processes. You can confidently use this powder in L-PBF, DED, and binder jet systems, including both spherical and MIM size applications.

Conclusion

At Reade Advanced Materials, our mission is unwavering: to equip manufacturers with nothing less than the best. We’re on a mission to provide manufacturers with the finest materials, and AM TZM Powder is the newest addition to our line of high-quality additive manufacturing materials. With its fully alloyed composition, outstanding flowability, and diverse applications, this product opens new possibilities for your AM projects.

To learn more about AM TZM Powder and explore how it can elevate your additive manufacturing endeavors, please visit our product page or contact our sales team. We would be thrilled to partner with you in creating innovative and high-quality 3D-printed components that can shape the future!